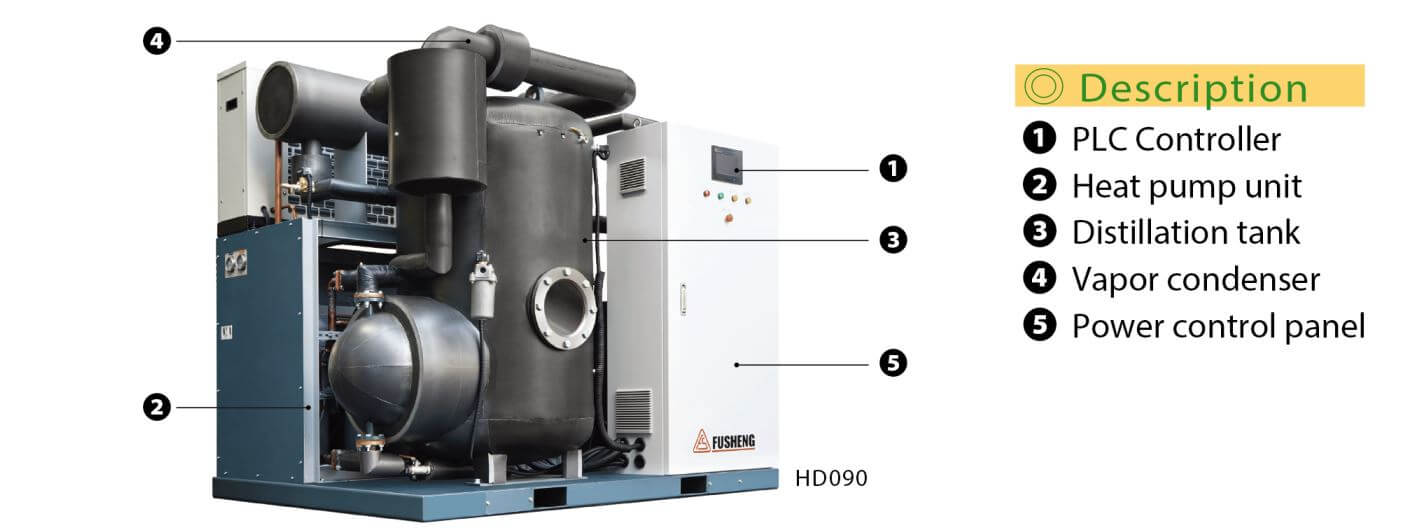

【Product】Vacuum distillation

Features

- Apply a new vacuum evaporation and condensation technology

- Adopt a high efficiency scroll heat pump compressor

- Use of environmental friendly refrigerant R134a and hot pipe heating design

- Safe and water-sealed vacuum pump

- Achieve low temperature vacuum distillation operation mode

- Compact unit design

- Reach the minimum operating cost

- Drastically reduce COD values

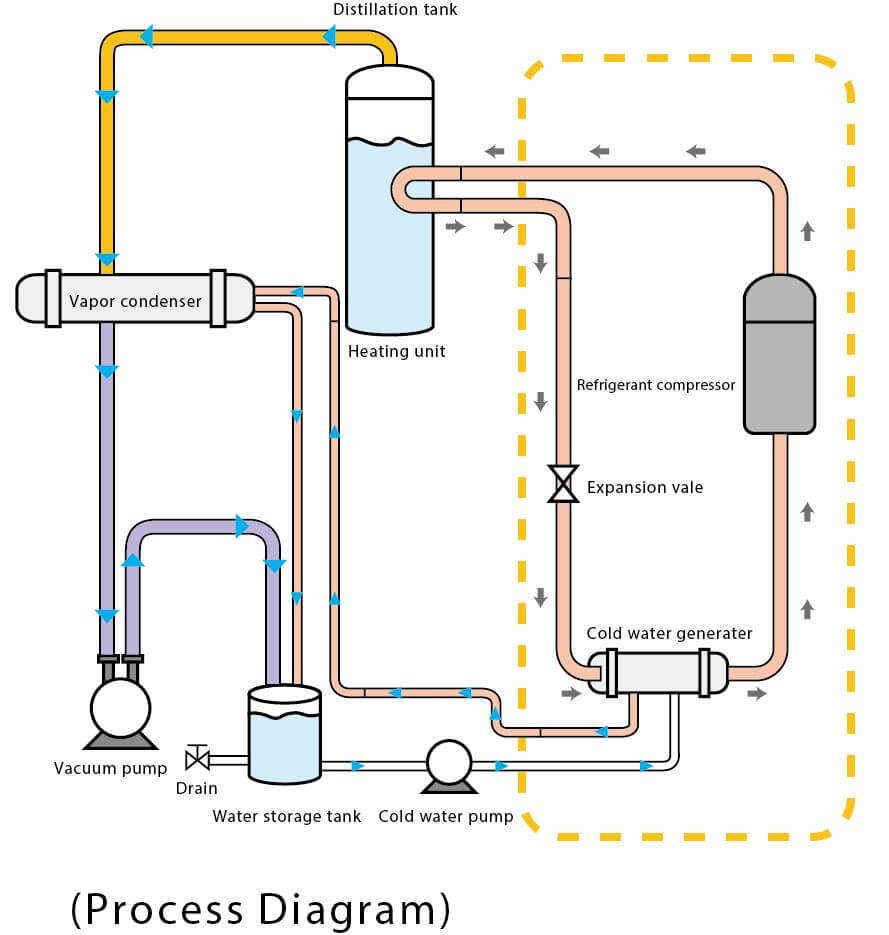

Actuation

1、 After feeding wastewater into the tank, the process of distillation could be started. Heat produced by the heat pump is transferred to the distillation tank. Since the tank is kept in vacuum condition by a vacuum pump, the water inside would boil at 40-60℃. The vapor would then condensed into cold water.

2、 The heat pump would continue providing energy to the tank.Under vacuum condition, it is possible to keep the wastewater at boiling stage. Once the majority of water has been vaporized and removed from wastewater, the fluid inside the tank would then become a concentrate. The concentrate could be disposed and the distilled water might be reused as reclaimed water depending on its quality.

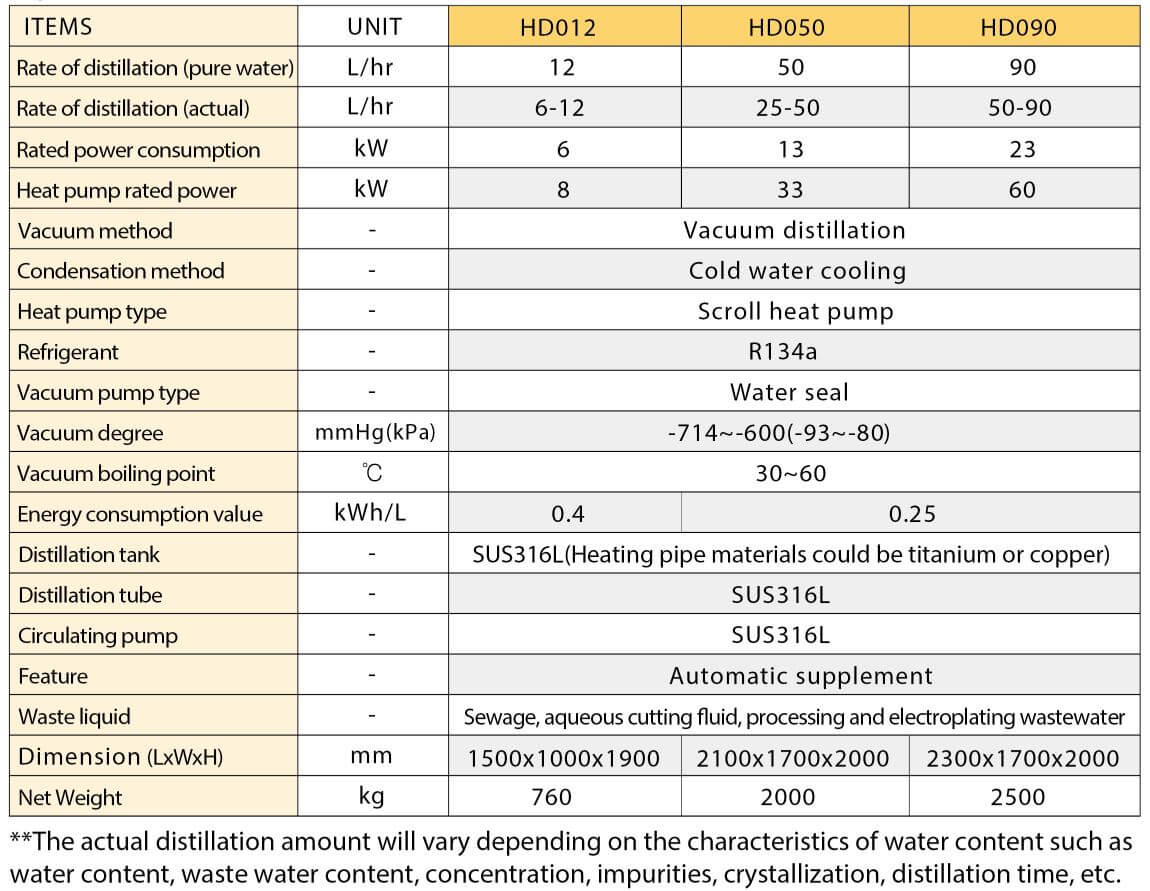

Specifications

Processing flow

Scope of application

1. Metal cutting wastewater

2. Electroplating wastewater

3. Degreasing wastewater

4. Leather wastewater

5. Dyeing and finishing wastewater

6. Desalination

The most eco-friendly and economical wastewater-treatment equipment [vacuum distillation] can decrease the industrial wastewater by 1/20 of the original, and significantly lower the value of COD. The recycled water can also be reused to achieve the zero discharge green environmental protection goal.

The high-efficiency scroll heat pump compressor can process wastewater ranging from 200 liters to 2000 liters per day, depending on different modes of the machine. With vacuum distillation technology, water will be boiled at 40-60 degrees. It means that one liter of processing fee is less than one NTD, greatly reducing the energy consumption during use. The building area of this equipment is small, both the efficience to enhance corporate image and reduce corporate costs, creating a value target of economic and environmental co-prosperity.